FASTFORM – AUTOMATIC INLINE BELLING MACHINE

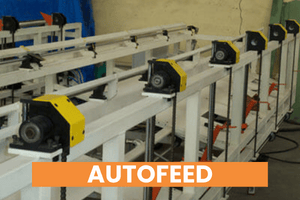

FASTFORM is our fully AUTOMATIC INLINE BELLING MACHINE for all your socketing needs. With a dual oven and heating and cooling cycles, it can handle SOLVENT CEMENT SOCKETS, SWR SOCKETS or ‘O’ RING PRESSURE (ELASTOMERIC) SOCKETS with accuracy and precision. It also has the capability to produce up to a high number of sockets accurately and efficiently. For even more convenience, a collection table can be added for socketing needs from dual extrusion lines.

No matter what type of socket you need, FASTFORM can provide perfect shapes with ease.

FASTFORM is a versatile and efficient bi-oriented pipe socketing machine designed to give you perfect socket shapes every time.

FASTFORM 90 & 110

- Both these machines are fully Automatic Inline and capable to make Solvent Cement Sockets as well as SWR Sockets.

- It can also take care of Socketing needs from Dual Extrusion Lines using a special Collection Table that can be added to the Machine.

- These are High Output, High Efficiency machines and capable to produce upto 400 Sockets per hour.

FASTFORM 250

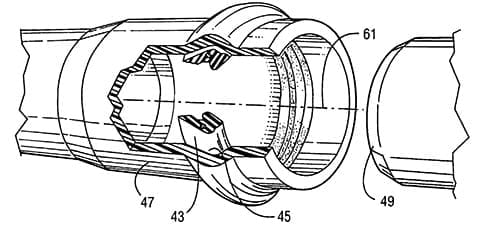

Introducing the Fully Automatic Inline Belling Machine for rigid PVC pipes to produce SOLVENT CEMENT SOCKETS, SWR SOCKETS or ‘O’ RING PRESSURE (ELASTOMERIC) PIPE SOCKETS from 50mm to250mm. This is Dual Oven Belling Machine for High Productivity and producing a perfect shape required for a Socket. The machine is completely Automatic with feeding of the Pipe directly from the Cutter conveyed to the First Oven then the Second Oven and thereafter Socketing. The finished Pipes falls directly on the Tilt Table or Trolley of the Customer. The machine is multipurpose and can use the following belling / socketing tools:

FASTFORM 200

This is semi automatic in Line or off Line Belling Machine. It is suitable to make SOLVENT CEMENT SOCKETS or O RING PRESSURE PIPE SOCKETS from 63mm upto 200mm.

The machine guaranties a precise of the internal diameter and above all the socket is perpendicular to the axis of the pipe. The cycle time being short due to the combined heating and socketing cycle allows high production.

The high production and a perfect socket shape allows you to be ahead of the competition with a superior product in the market.

As soon as the pipe is inserted manually the complete heating, cooling and socketing cycle is automatic. The only manual operation is inserting the pipe on the mandreal and removing the pipe from the machine when the entire process is complete.

FASTFORM 400

Introducing the Fully Automatic Inline Belling Machine for rigid PVC pipes to produce SOLVENT CEMENT SOCKETS, SWR SOCKETS or ‘O’ RING PRESSURE (ELASTOMERIC) PIPE SOCKETS from 63mm to 400mm. This is Dual Oven Belling Machine for High Productivity and producing a perfect shape required for a Socket. The machine is completely Automatic with feeding of the Pipe directly from the Cutter conveyed to the First Oven then the Second Oven and thereafter Socketing. The finished Pipes falls directly on the Tilt Table or Trolley of the Customer. The machine is multipurpose and can use the following belling / socketing tools:

IMAGES

VIDEOS

FASTFORM 110

FASTFORM 400+ RINGFIT

TECHNICAL SPECIFICATIONS

| Model No. | Min. Dia. (in mm) | Max. Dia. (in mm) | Max. Pipe Thickness (in mm) | Installed Power (kw) (approx) | Socket Types |

|---|---|---|---|---|---|

| FASTFORM 90 | 20 | 90 | 10 | 13.2 | Solvent Cement & SWR |

| FASTFORM 110 | 20 | 110 | 10 | 13.2 | Solvent Cement & SWR |

| FASTFORM M200-1T | 63 | 200 | 5 | 4.8 | Solvent Cement, SWR, Elastomeric Ring |

| FASTFORM M200-2T | 63 | 200 | 5 | 9.6 | Solvent Cement, SWR, Elastomeric Ring |

| FASTFORM 250 | 50 | 250 | 25 | 26.0 | Solvent Cement, SWR, Elastomeric Ring |

| FASTFORM 400 | 63 | 400 | 32 | 43.0 | Solvent Cement, SWR, Elastomeric Ring |